Acoustic emission inspection (AE)

Acoustic emission (AE) is the phenomenon of radiation of acoustic (elastic) waves in solids that occurs when a material undergoes irreversible changes in its internal structure, for example as a result of crack formation or plastic deformation due to aging, temperature gradients or external mechanical forces. In particular, AE is occurring during the processes of mechanical loading of materials and structures accompanied by structural changes that generate local sources of elastic waves. This results in small surface displacements of a material produced by elastic or stress waves generated when the accumulated elastic energy in a material or on its surface is released rapidly. The waves generated by sources of AE are of practical interest in methods used to capture AE in a controlled fashion, for study and/or use for inspection of structural integrity, quality control, system feedback, process monitoring, and others.

|

AE is commonly defined as transient elastic waves within a material, caused by the rapid release of localized stress energy. Hence, an event source is the phenomenon which releases elastic energy into the material, which then propagates as an elastic wave. Acoustic emissions can be detected in frequency ranges under 1 kHz, and have been reported at frequencies up to 100 MHz, but most of the released energy is within the 1 kHz to 1 MHz range. Rapid stress-releasing events generate a spectrum of stress waves starting at 0 Hz, and typically falling off at several MHz.

The three major applications of AE techniques are: 1) source location - determine the locations where an event source occurred; 2) material mechanical performance - evaluate and characterize materials/structures; and 3) health monitoring - monitor the safety operation of a structure, i.e. bridges, pressure containers, and pipe lines, etc.

Acoustic emission types

- Material acoustic emission - acoustic emission generated by a local and dynamic material structure rearrangement.

- Leakage acoustic emission– acoustic emission generated by hydrodynamic and (or) aerodynamic phenomena when liquid or gas leaks through the through discontinuity of the test object.

- Friction acoustic emission - acoustic emission generated by solid surface frictions.

- Phase transition acoustic emission - acoustic emission related to phase transitions in substances and materials.

- Magnetic acoustic emission - acoustic emission related to the emission of sound waves when materials undergo magnetization reversal.

- Radiation interaction acoustic emission - acoustic emission generated as a result of an emission non-linear interaction with substances and materials.

- Chemical and electrochemical reaction acoustic emission - acoustic emission generated as a result of the behavior of chemical and electrochemical reactions, including different corrosion processes.

From the above-mentioned AE types the first three ones have been used for testing industrial facilities more often.

The AE complex’s allows performing measurements of the following objects:

- Pressure-operated vessels

- Process pipelines

- Process equipment of compressor and gas-distributing stations

- Field gas pipelines

- Main gas pipelines

- Lifting devices

- Bridge structures

- Gas pipelines

Advantages and disadvatanges of the AE method

Advantages:

- Registers only developing defects

- Highly sensitive to growing defects, corresponds to the identification of a crack step with a length of 1 µm by a value of 1 µm.

- Has the feature of “integrality” which means that it is possible to control the whole object by using one or several AE transducers installed and fixed on the object’s surface.

- The AE method’s remote state – the operator can exercise control over the test object that is far away to the operator.

- The form, position and orientation of a defect are insignificant for the AE method.

- The AE method has less limitations related to properties and structures of construction materials than others NDT methods.

- The AE method is believed to have the maximum efficacy/cost ratio in the field of NDT and TD.

Disadvantages:

- Метод предъявляет повышенные требования к квалификации операторов.

- АЭ контроль объектов проводится только при создании или существовании в конструкции напряженного состояния.

- Применение метода АЭ ограничивается в ряде случаев из-за трудности выделения сигналов АЭ на фоне помех.

Acoustic Emission system composition

Acoustic Emission complex A-Line 32D (DDM)

- Central information computer station

- Data transmission cable

- Date collection modules

- Line terminators

- Acoustic emission transducer

Examples of Acoustic Emission method application

|

Crossings of pipelines |

Equalizing valves and interconnecting pipings |

|

Pipeline crossing under motorway and rail roads |

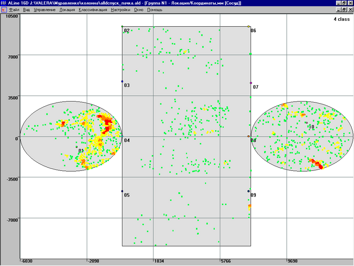

Control data presentation

10 000 m3 storage tank. Defects of the bottom.

Adsorption plant

Pressure vessel

Process gas pipelines and hook-ups

The flexibility and convenience of control over objects of different type, form, length and accessibility are provided for by the use of different connection schemes.

Acoustic emission complexes based on a module connection scheme and on a radio-channel allow varying diagnostics means to a rather great extent, including organizing continuous monitoring systems (technical condition control) of objects which enhances the reliability of their operation.

“NTC “Neftegazdiagnostika” LLC uses a full range of cutting-edge devices of NDT. They include equipment for visual and dimensional testing, ultrasound testing, probe-coil, magnetic, eddy current, pig inspection, electrometric testing and acoustic emission testing.

Nowadays the acoustic emission (AE) method is one of the most promising methods of NDT of different types of objects.

AE Control International Standards:

- E569, Standard Practice for Acoustic Emission Monitoring of Structures During Controlled Stimulation

- E650, Standard Guide for Mounting Piezoelectric Acoustic Emission Sensors

- E976, Standard Guide for Determining the Reproducibility of Acoustic Emission Sensors Response

- E1106, Standard Method for Primary Calibration of Acoustic Emission Sensors

- E1211, Standard Practice for Leak Detection and Location Using Surface-Mounted Acoustic Emission

Sensors

- E1419, Standard Test Method for Examination of Seamless, Gas-Filled, Pressure Vessels Using

Acoustic Emission

- E1736, Standard Practice for Acousto-Ultrasonic Assessment of Filament-Wound Pressure Vessels

- E1781, Standard Practice for Secondary Calibration of Acoustic Emission Sensors

- E1930, Standard Test Method for Examination of Liquid Filled Atmospheric and Low Pressure Metal

Storage Tanks Using Acoustic Emission.

-E2374, Standard Guide for Acoustic Emission System Performance Verification.

-

18 Aug 2018NTC completed the development of the draft requirements of the rules for the offshore underwater pipelines repair, commissioned by the Russian Maritime Register of Shipping.

-

10 Nov 201608.11.2016 Russia was visited by representatives of the Indian Joint Industrial Delegation and the management of NTC-NGD India.30 Sep 2016The tests were successfully carried out in cooperation with experts of “Multi-Business Company “KASKAD”, LLC from September 21, 2016 to September 29, 2016.

29 Aug 2016Management from NTC-NGD India along with a Joint Industrial Delegation from India, outline plans to visit Russia in the 1st half of October 2016.20 Jul 2016In August 2016 takes place the official opening of “NTC “Neftegazdiagnostika” foreign representative office in the Republic of India.06 Apr 201627.03.2016 - 05.04.2016 Viktor Leshchenko, Director General “NTC “Neftegazdiagnostika” LLC, visited Calcutta (India) to participate ...

09 Mar 2015A sole agency agreement was signed between NTC NEFTEGAZDIAGNOSTIKA LLC and Abdel Hadi Abdullah Al-Qahtani & Sons Company

12 Sep 2014On September 12, the laboratory VNIPI "VZRYVGEOFIZIKA" conducted

03 Sep 2014New website launched!

15 Jul 2013Inline inspection of main gas line Nord Stream pipeline 1-East, Dn 1220×34.6/41 mm, 1224.4 km long

Inline inspection of main gas line Nord Stream pipeline 2-East, Dn 1220х34.6/41 mm, 1224.4 km long

14 Aug 2012Segment 1, gas pipeline Ø 1220 mm. OPF – BS-2, 295 km long.

Segment 2, gas pipeline Ø 1220 mm. BS-2 – OET, 328 km long.

03 Jun 2012Inline inspection of the offshore oil pipeline "OIFP D-6 – oil gathering facility "Romanovo", Dn 273x18, 51.812 km long.

11 Mar 2012Integrated diagnostics of sub-sea oil pipeline "OIFP – SPM, oil field n.a. Yu. Korchagin" started.

10 Mar 2012Installation and dismantling of temporary pig launchers/receivers

Pipeline cleaning, gauging, geometry inspection, magnetic pig inspection

Subsea external inspection using ROVs

15 Jan 2011Cleaning of the offshore oil pipeline "OIFP – SPM, oil field n.a. Yu. Korchagin", Dn 325×16.